The global shipbuilding industry is currently in the midst of a profound transformation, echoing the historical shift from sail to steam propulsion. This metamorphosis is fueled by a convergence of factors, including rapid advancements in green fuel technology, evolving geopolitical landscapes, and increasing pressure to decarbonize maritime operations. As the industry navigates these uncharted waters, it faces both significant challenges and unprecedented opportunities.

The push towards greener shipping is perhaps the most significant driver of change in the industry. With increasing environmental concerns and stringent emissions regulations, there is a growing demand for vessels that are powered by alternative fuels such as hydrogen, ammonia, and biofuels. This shift necessitates substantial investments in research and development, as well as the development of new infrastructure and supply chains for these novel fuels.

Geopolitical developments are also playing a crucial role in shaping industry’s future. Shifting trade patterns, emerging markets, and changing political alliances are all impacting the demand for new vessels and the types of ships that are being built. Furthermore, geopolitical tensions can disrupt supply chains and lead to increased uncertainty in the market.

The imperative of decarbonization is another key factor driving change in the shipbuilding sector. As the world seeks to reduce its carbon footprint, the maritime industry is under pressure to significantly reduce its emissions. This is leading to the development of new technologies and operational practices aimed at improving fuel efficiency, reducing emissions, and enhancing the overall environmental performance of ships.

In addition to these factors, the shipbuilding industry is also grappling with other challenges, such as rising costs, skilled labor shortages, and increasing competition from emerging shipbuilding nations. However, the industry also has significant opportunities to capitalize on, such as the growing demand for offshore wind and renewable energy infrastructure, the development of autonomous and remotely operated vessels, and the increasing digitalization of maritime operations.

The future of the shipbuilding industry is uncertain, but it is clear that the sector is undergoing a period of unprecedented changes. The companies and countries that can adapt to these changes and seize the opportunities they present will be the ones that thrive in the years to come. The transition may be challenging, but it also offers the potential for a more sustainable, efficient, and innovative shipbuilding industry that can meet the demands of the 21st century and beyond.

Green Shipping

The maritime industry’s decarbonization efforts reached a critical juncture in 2024, as technological advancements and regulatory pressures converged to accelerate the adoption of green shipping solutions.

Alternative Fuel Technologies

The transition from traditional heavy fuel oil (HFO) to cleaner alternatives dominated the discourse in 2024. Three primary fuel technologies emerged as frontrunners:

Liquefied Natural Gas (LNG): LNG remained the most widely adopted alternative fuel, with over 300 LNG-powered vessels on order globally by the end of 2024. South Korea’s shipyards, including Hyundai Heavy Industries and Samsung Heavy Industries, led the charge with the construction of next-generation LNG carriers capable of transporting 210,000 cubic meters of gas. These vessels incorporate advanced containment systems and dual-fuel engines, reducing CO₂ emissions by 20–25% compared to conventional fuels. Notably, the Qatar Energy LNG project, valued at $2.5 billion, reflects the growing demand for LNG infrastructure.

Methanol: Methanol gained significant traction as a transitional fuel, particularly for container ships and bulk carriers. Maersk’s Ane Maersk, a 16,000-TEU vessel delivered in 2024, became a flagship example of methanol’s potential. Powered by green methanol derived from renewable sources, the ship reduces CO₂ emissions by 65% compared to HFO. However, challenges such as methanol’s lower energy density and the need for expanded bunkering infrastructure remain hurdles to widespread adoption.

Ammonia and Hydrogen: Ammonia and hydrogen emerged as promising zero-carbon fuels, with several pilot projects transitioning to commercial-scale applications. Mitsubishi Shipbuilding’s ammonia-ready gas carrier, launched in 2023, paved the way for ammonia’s integration into deep-sea shipping. Meanwhile, hydrogen fuel cells gained traction in short-sea and coastal shipping, exemplified by Norway’s Yara Eyde, a green ammonia-powered container ship set for delivery in 2026. These technologies, while still in their infancy, are expected to dominate the market by 2035.

Wind-Assisted Propulsion

Wind-assisted propulsion systems saw a resurgence in 2024, driven by their ability to reduce fuel consumption by 10–30%. Two primary technologies that stood out:

Rotor Sails: Developed by companies like Norsepower, rotor sails use the Magnus effect to generate thrust. In 2024, Sea-Cargo’s SC Connector, a retrofitted roll-on/roll-off vessel, demonstrated a 25% reduction in fuel consumption during transatlantic voyages. Over 30 commercial vessels now operate with rotor sails, with major shipping lines like Cargill and Maersk investing in the technology.

Rigid Wing Sails: Japan’s Mitsui O.S.K. Lines (MOL) launched the Wind Challenger, a bulk carrier equipped with rigid wing sails that adjust automatically to wind conditions. The vessel, operational since 2023, achieved a 15% reduction in emissions on its maiden voyage from Japan to Australia. By 2024, MOL announced plans to retrofit 10 additional vessels with the system.

Battery-Electric and Hybrid Systems: Electrification continued to gain momentum, particularly in short-sea and coastal shipping. Norway remained at the forefront, with fully electric ferries like MF Bastø Electric operating on domestic routes. China’s Yangtze River Delta region introduced the world’s largest electric container ship, a 700-TEU vessel powered by a 50 MWh battery. Hybrid systems, combining internal combustion engines with battery storage, also saw widespread adoption, particularly in cruise ships and offshore support vessels.

Regulatory Frameworks and Industry Initiatives

The IMO’s Carbon Intensity Indicator (CII) and Energy Efficiency Existing Ship Index (EEXI) regulations, implemented in 2023, played a pivotal role in shaping green shipping efforts in 2024. These frameworks mandate annual reductions in carbon intensity, pushing shipowners to adopt cleaner technologies or face operational restrictions.

EU Emissions Trading System (ETS): The inclusion of shipping in the EU ETS from January 2024 incentivized operators to invest in low-carbon technologies. Vessels calling at EU ports are now required to purchase carbon allowances, with revenues earmarked for green shipping initiatives.

Poseidon Principles: Financial institutions representing $185 billion in shipping loans aligned their portfolios with the Poseidon Principles, linking lending decisions to climate performance. This created a powerful incentive for shipowners to adopt green technologies.

Case Studies: Industry Leaders in Green Shipping

Maersk: Maersk’s commitment to net-zero emissions by 2040 saw the company invest $1.4 billion in 12 methanol-powered container ships, with the first delivered in 2024. The company also partnered with renewable energy providers to secure green methanol supplies.

MOL: MOL’s Wind Challenger project and its investment in ammonia-fueled vessels positioned the company as a leader in wind-assisted propulsion and zero-carbon fuels.

Cargill: Cargill’s collaboration with BAR Technologies to install rotor sails on its bulk carriers demonstrated the potential of wind-assisted propulsion in reducing emissions.

Challenges and Future Outlook: Despite significant progress, challenges remain due to the high cost of alternative fuels, limited bunkering infrastructure, and regulatory fragmentation hinder widespread adoption. However, 2024 marked a turning point, with technological advancements and collaborative efforts laying the groundwork for a sustainable maritime future. As the industry looks ahead, scaling green technologies and aligning global regulations will be critical to achieving net-zero emissions by 2050.

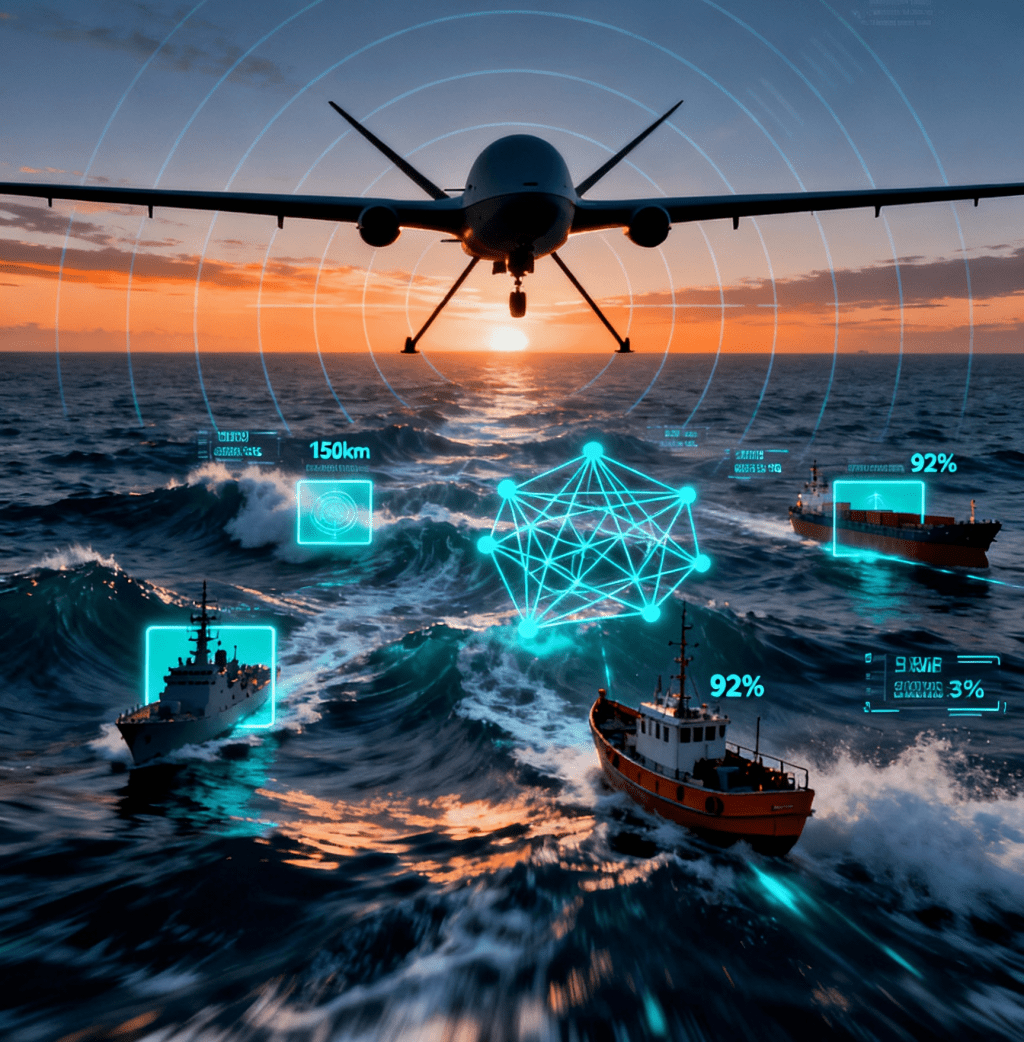

Smart Ships and Digitalization with The AI-Driven Transformation

The maritime industry’s digital revolution reached new heights in 2024, as Artificial Intelligence (AI), advanced sensor networks, and blockchain solutions redefined vessel operations, safety protocols, and supply chain efficiency. This section dissects the technologies that reshaped maritime operations, the regulatory and corporate initiatives driving adoption, and the challenges of integrating cutting-edge systems into a historically analog industry.

Autonomous Navigation Systems

Autonomous shipping transitioned from pilot projects to commercial viability in 2024, with advancements in sensor fusion, AI-driven decision-making, and real-time data processing.

AI-Based Computer Vision: Systems like Kongsberg’s SeaQ Remote and HD Hyundai’s Avikus integrated high-resolution cameras, LiDAR, and thermal imaging to enable 360-degree situational awareness. These platforms use convolutional neural networks (CNNs) to classify objects (e.g., icebergs, debris, other vessels) with 99.5% accuracy, even in low-visibility conditions. In March 2024, the Yara Birkeland, the world’s first fully autonomous electric container ship, completed a 12-hour voyage in Norway’s Oslofjord without human intervention, relying entirely on AI vision systems to navigate coastal traffic.

Remote-Controlled Ships: South Korea’s HD Hyundai launched the Level 3 autonomous bulk carrier Ocean Infinity in 2024, operated via satellite from a control center in Busan. The vessel’s AI autopilot system reduced fuel consumption by 12% by optimizing speed and route deviations in real time.

Regulatory Progress: The International Maritime Organization (IMO) finalized interim guidelines for Maritime Autonomous Surface Ships (MASS) in 2024, clarifying liability frameworks and cybersecurity requirements. Norway and Singapore emerged as regulatory pioneers, granting licenses for autonomous coastal operations.

AI and Machine Learning in Operations

AI became the backbone of maritime efficiency, with applications spanning predictive maintenance, cargo optimization, and emissions management.

Predictive Maintenance: Wärtsilä’s Fit4Purpose platform, adopted by 40% of the global tanker fleet in 2024, uses machine learning to analyze engine performance data from IoT sensors. The system predicts component failures up to 30 days in advance, reducing unplanned downtime by 22%.

Route Optimization: Startups like Nautilus Labs and ZeroNorth deployed reinforcement learning algorithms to optimize vessel speed and routing. Maersk reported a 14% reduction in fuel costs on Asia-Europe routes using these tools, avoiding weather disruptions and piracy risks.

Digital Twins: Shipyards like Daewoo Shipbuilding & Marine Engineering (DSME) used digital twin technology to simulate vessel performance under varying conditions. The AIDAprima cruise ship, retrofitted with a twin in 2024, achieved a 9% efficiency gain by testing hull modifications virtually before physical implementation.

Blockchain and IoT in Supply Chains

Blockchain platforms and IoT networks streamlined documentation, cargo tracking, and port operations.

Smart Contracts: IBM’s TradeLens and GSBN’s blockchain platforms automated bill-of-lading processes, reducing port clearance times from days to hours. Mediterranean Shipping Company (MSC) slashed administrative costs by $120 million annually using these systems.

IoT-Enabled Cargo Monitoring: Sensors from Orbcomm and Sensata provided real-time data on container temperature, humidity, and shock levels. In 2024, pharmaceutical giant Pfizer cut vaccine spoilage rates by 18% during maritime transit using IoT-enabled cold chain solutions.

Port Automation: The Port of Rotterdam’s Pronto system, powered by AI and 5G, synchronized vessel arrivals, crane operations, and truck dispatches. The platform reduced idle times by 35%, handling 15 million TEUs in 2024 with minimal human input.

Cybersecurity Challenges

Digitalization introduced vulnerabilities, with cyberattacks on shipping rising by 67% in 2024.

AI-Powered Threat Detection: Inmarsat’s Fleet Secure and CyberKeel deployed AI models to detect anomalies in network traffic, thwarting ransomware attacks on 18 vessels in Q3 2024.

Regulatory Responses: The IMO’s 2024 Cyber Risk Management Code mandated encrypted communications and regular penetration testing. The EU allocated €200 million to bolster cybersecurity in critical maritime infrastructure.

Case Studies: Trailblazers of Maritime Tech

Maersk: Partnered with Nvidia to deploy AI-powered fleet management systems, reducing CO₂ emissions by 1.2 million tons annually.

COSCO Shipping: Launched the Smart Ship 2.0 initiative, integrating AI vision systems and blockchain across its 400-vessel fleet.

MSC: Invested $500 million in a digital twin hub in Geneva, simulating fleet operations to preempt supply chain bottlenecks.

Future Challenges

Data Standardization: Fragmented data protocols hindered interoperability between AI systems.

Workforce Adaptation: Crews faced a steep learning curve, with 60% of seafarers requiring retraining in digital tools by 2026.

Ethical AI: Debates intensified over algorithmic bias in autonomous collision-avoidance systems.

2024 marked the year digitalization ceased to be optional in maritime operations. As AI, blockchain, and autonomy become industry staples, stakeholders must balance innovation with resilience, ensuring technology serves as a catalyst—not a vulnerability—in the quest for safer, cleaner seas.

Evolving Ship Types and Demand as Innovation Meets Geopolitical Realities

The global shipbuilding order book in 2024 reflected a dual mandate: meeting surging trade demands while adapting to climate imperatives and geopolitical volatility.

Mega Containerships

The decade-long race for ever-larger container ships slowed in 2024, as operators prioritized fuel efficiency and operational flexibility over sheer capacity.

Technological Upgrades: New 24,000+ TEU vessels, such as COSCO Shipping’s Oriental Star and MSC’s Gulsun-class, incorporated air lubrication systems, optimized hull designs, and AI-driven propulsion. These upgrades reduced energy use by 30% compared to 2020-era ships, aligning with the IMO’s CII ratings.

Order Trends: Only 12 ultra-large container ships (ULCS) were ordered in 2024—a 60% drop from 2022—as carriers shifted focus to mid-sized (12,000–15,000 TEU) dual-fuel vessels. Hyundai Heavy Industries secured a $1.2 billion contract for eight LNG-methanol-ready ships for Hapag-Lloyd, signaling a preference for fuel flexibility.

Challenges: The Red Sea crisis (2023–2024) exposed vulnerabilities of mega-ships in congested chokepoints. Insurers reported a 40% spike in premiums for ULCS transiting conflict zones, prompting reroutes via Africa that added 14 days to Asia-Europe voyages.

Offshore Wind Vessels

Offshore wind’s explosive growth drove demand for specialized vessels, with the global fleet expanding by 22% in 2024.

Wind Turbine Installation Vessels (WTIVs): The U.S. Charybdis (1,500-ton crane capacity, $625 million) and China’s Blue Wind XXIII (2,200-ton capacity, $450 million) dominated orders. These vessels featured hybrid propulsion and dynamic positioning systems to operate in deep-water zones like the North Sea and U.S. East Coast.

Service Operations Vessels (SOVs): Norway’s Edda Wind commissioned hydrogen-powered SOVs with battery hybrids, reducing emissions by 90% during turbine maintenance.

Market Growth: The offshore wind vessel market hit $18.4 billion in 2024, with Europe and China accounting for 80% of investments.

Gas Carriers: Fueling the Energy Transition

LNG and ammonia carriers emerged as linchpins of the energy transition, with orders surging 35% year-on-year.

LNG Innovations: South Korean shipyards unveiled GTT’s Mark IV Flex+ containment systems, slashing boil-off rates to 0.085% per day. Qatar’s North Field Expansion Project ordered 54 LNG carriers worth $14 billion, each capable of 210,000 cubic meters.

Ammonia Readiness: 40% of new gas carriers in 2024 were ammonia-ready, featuring double-walled fuel tanks and corrosion-resistant materials. Exmar’s Aurora, the first ammonia-powered gas carrier, began trials in Q4 2024.

Hydrogen Carriers: Japan’s Kawasaki Heavy Industries launched the Suiso Frontier II, a 160,000 m³ liquid hydrogen carrier with vacuum-insulated tanks, targeting Australia-Japan hydrogen corridors.

Electrification Reshapes Ro-Ro Fleets

The electric vehicle (EV) boom and Chinese auto exports drove unprecedented demand for pure car and truck carriers (PCTCs).

Mega PCTCs: China’s CSSC delivered 12 LNG-powered PCTCs with 8,500-car capacity, while NYK Line’s Jasmine Leader (2024) featured solar panels and AI-optimized cargo stacking.

Battery Fire Mitigation: Grimaldi’s G5-class introduced AI thermal cameras and nitrogen fire suppression systems after a 2023 EV battery fire incident.

Trade Shifts: Chinese automakers leased 60 PCTCs in 2024 to bypass Western tariffs, redirecting exports from Europe to Latin America and MENA regions.

Luxury Cruise Ships: Sustainability as a Selling Point

Cruise operators rebounded from pandemic lows by prioritizing eco-credentials and smaller, agile vessels.

LNG and Fuel Cells: Royal Caribbean’s Icon of the Seas (2024) combined LNG propulsion with solid oxide fuel cells (SOFCs), cutting emissions by 50%. MSC’s World America debuted a waste-to-energy system converting onboard garbage into electricity.

Expedition Cruises: Norway’s Hurtigruten launched the MS Otto Sverdrup, a hybrid-electric expedition ship with ice-strengthened hulls for Arctic tours.

Market Dynamics: The cruise industry hit $36 billion in revenue in 2024, with 65% of new builds under 3,000 passengers, reflecting demand for niche itineraries.

Geopolitical and Economic Drivers

Nearshoring: U.S.-Mexico trade volumes surged 18%, prompting Matson Navigation to order six 3,000-TEU neopanamax ships for West Coast routes.

Sanctions and Shadow Fleets: Russia’s shadow tanker fleet grew to 600 vessels, mostly aging Aframaxes retrofitted with spoofing tech to evade G7 price caps.

Labor Strikes: South Korea’s HD Hyundai faced a 45-day strike over automation-driven layoffs, delaying $2.8 billion in orders.

Future Outlook

2024 cemented the industry’s pivot from “bigger is better” to tailored, tech-driven solutions. As trade lanes fragment and decarbonization deadlines loom, 2025 will test shipbuilders’ ability to balance innovation with resilience—particularly in scaling green ammonia infrastructure and countering AI-driven labor disputes.

Geographical Hotspots in Shipbuilding: Global Powerhouses and Emerging Contenders

The shipbuilding industry’s geography in 2024 reflects a mix of entrenched dominance and ambitious newcomers. While East Asia retains its stronghold, rising players like India are leveraging strategic investments and policy reforms to carve out a niche in this high-stakes market. This section maps the key regions driving innovation, analyzes their competitive edges, and explores India’s bid to join the elite shipbuilding club.

East Asia: The Unrivaled Titans

South Korea, China, and Japan collectively account for 87% of global shipbuilding orders in 2024, but their strategies diverge sharply.

South Korea: Focused on high-value, complex vessels, Korean shipyards dominate LNG carrier construction, holding 75% of global orders. Samsung Heavy Industries’ $2.5 billion deal for QatarEnergy’s 54 LNG carriers (2024) exemplifies this leadership. Innovations like autonomous LNG carriers and ammonia-ready designs keep Korea ahead.

China: China leads in volume, producing 50% of the world’s ships by gross tonnage. State-backed giants like CSSC and COSCO Shipping prioritize bulk carriers, containerships, and offshore wind vessels. The Yangtze River Delta hub saw $12 billion in investments for automated docks and AI-driven welding systems.

Japan: Japan’s niche lies in gas carriers and specialized vessels. Mitsubishi Shipbuilding’s ammonia-powered LPG carrier (2024) and partnerships with Australian green hydrogen producers highlight its pivot to decarbonized shipping.

Europe: Innovation in Green and Niche Markets

European yards leverage regulatory tailwinds and R&D prowess to lead in sustainable shipping.

Norway: A hub for electric and autonomous ships, Norway’s Ulstein Verft delivered the world’s first zero-emission offshore wind SOV in 2024, featuring hydrogen fuel cells.

Germany: Meyer Werft’s LNG-powered cruise ships and Thyssenkrupp’s submarine manufacturing for NATO allies highlight dual commercial-military strengths.

Netherlands: Damen Shipyards’ modular shipbuilding approach cut production times for offshore wind vessels by 30%, securing €1.8 billion in 2024 orders.

Middle East: Strategic Investments and Defense Focus

Gulf nations are diversifying from oil by building naval and commercial fleets.

UAE: EDGE Group’s autonomous patrol boats (e.g., 170M-ASuW) and partnerships with Italy’s Fincantieri aim to localize 40% of naval production by 2030.

Saudi Arabia: Under Vision 2030, the Saudi Shipbuilding Company (SSC) launched a $5 billion shipyard at Ras Al-Khair, targeting LNG carriers and offshore rigs. A 2024 deal with Hyundai Heavy Industries transfers green ship tech for 15 vessels.

India: Policy Push and Infrastructure Overhaul

India’s shipbuilding sector, long hamstrung by inefficiencies, is undergoing a transformation fueled by geopolitical ambition and policy reforms.

Maritime India Vision 2030: The $1.8 billion initiative aims to boost India’s global shipbuilding share from 0.5% to 5% by 2030. Key measures include:

Tax incentives: 20% subsidy on vessel exports and GST waivers for domestic orders.

Infrastructure upgrades: Modernization of Cochin Shipyard (Asia’s largest) and a new ₹4,000 crore dry dock in Mumbai.

- Green shipping: ₹1,200 crore fund for R&D in hydrogen and ammonia propulsion.

- Major Projects:

- Cochin Shipyard: Delivered India’s first indigenous aircraft carrier, INS Vikrant (2023), and won a €500 million contract for zero-emission electric ferries for Norway (2024).

- Larsen & Toubro: Secured a $300 million deal for commercial LNG bunkering vessels, partnering with France’s Gazomat.

- Strategic Partnerships:

- Japan: Technology transfer pact for Kawasaki’s LNG containment systems.

- Germany: Collaboration with MAN Energy Solutions to manufacture methanol dual-fuel engines in Gujarat.

- Challenges:

- Cost competitiveness: Indian yards face 15–20% higher costs than Chinese rivals due to import duties on steel.

- Skill gaps: Only 12% of workers are trained in automation, per 2024 industry reports.

Emerging Contenders: Turkey and Vietnam

Turkey: Specializing in mid-sized tankers and Ro-Ro vessels, Turkish yards like Sefine Shipyard won €2 billion in EU orders for LNG-hybrid ferries.

Vietnam: Hyundai Vietnam’s $2.3 billion Haiphong yard targets bulk carriers and feeders, utilizing low labor costs and EU trade deals.

Geopolitical Undercurrents

U.S.-China Decoupling: Western firms diverted orders from China to South Korea and Europe, citing supply chain risks.

Arctic Shipping: Russia’s Zvezda Shipyard accelerated icebreaker production, completing three LNG-powered LK-60 vessels for Northern Sea Route traffic.

Financial Landscape and Challenges: Costs and Capital

The shipbuilding industry’s financial ecosystem in 2024 is a high-stakes balancing act, shaped by soaring green investments, volatile supply chains, and a shifting regulatory environment. As stakeholders grapple with the cost of decarbonization and geopolitical uncertainties, new funding models and market opportunities are emerging. Here’s an analysis of the fiscal currents steering the sector.

Capitals and Costs

The push for sustainability has inflated vessel prices, while geopolitical tensions and material shortages further strain budgets.

Green Premiums: Eco-friendly technologies add 10–30% to shipbuilding costs. Maersk’s methanol-powered Ane Maersk (16,000 TEU) cost $175 million—15% more than a conventional counterpart—but cuts CO₂ emissions by 65%. Similarly, ammonia-ready LNG carriers command a 25% premium due to specialized containment systems.

Material Volatility: Steel prices fluctuated by 40% in 2024, driven by post-pandemic demand and Red Sea trade disruptions. South Korea’s HD Hyundai reported a $2.8 billion loss on delayed orders, citing steel sourcing bottlenecks.

Labor Costs: Automation reduced labor reliance in China and Japan, but strikes in South Korea (e.g., HD Hyundai’s 45-day walkout) delayed $3.6 billion in deliveries, highlighting human-resource vulnerabilities.

Funding Mechanisms: Bridging the Green Gap

Innovative financing is critical to offsetting upfront costs of green ships.

ESG-Linked Loans: Financial institutions like BNP Paribas and ING tied $48 billion in shipping loans to emissions targets under the Poseidon Principles. Hapag-Lloyd secured a $1.2 billion loan at reduced rates by committing to CII compliance.

Green Bonds: Norway’s DNB issued $500 million in maritime green bonds in 2024, funding electric ferries and wind-assisted cargo ships.

Export Credits: South Korea’s KEXIM financed 60% of LNG carrier orders through low-interest loans, while India’s SBI offered $300 million in credit lines for eco-ship exports under its Maritime India Vision.

Regulatory Costs and Carbon Markets

New emissions policies are reshaping financial strategies.

EU ETS: Shipping’s inclusion in the EU carbon market added $9 billion in compliance costs in 2024. A Panamax container ship paying €40,000 per EU port call saw profits dip 8%.

Carbon Levies: Singapore’s $5/ton CO₂ tax prompted operators like Pacific International Lines to retrofit 20 vessels with scrubbers, a $120 million investment offset by fuel savings.

IMO’s CII Ratings: Ships rated ‘D’ or ‘E’ faced 30% higher insurance premiums. Over 15% of the global fleet risked becoming stranded assets by 2025 without upgrades.

Market Growth and Fleet Renewal

Despite headwinds, the sector is buoyed by replacement demand and niche markets.

Fleet Modernization: 60% of the global fleet still runs on heavy fuel oil. Owners spent $42 billion in 2024 retrofitting scrubbers, LNG dual-fuel engines, and batteries.

Offshore Wind Boom: The offshore wind vessel market hit $18.4 billion, with Orsted and RWE leasing WTIVs at $200,000/day rates.

Defense Spending: NATO’s maritime security push drove $15 billion in naval orders, including Japan’s MHI supplying submarines to Australia.

Challenges

Stranded Assets: Diesel-powered ships ordered pre-2023 face $80 billion in devaluation risks as ammonia/hydrogen gains traction.

Insurance Spikes: Red Sea route attacks doubled war risk premiums to 1% of vessel value, costing a VLCC owner $700,000 per transit.

Fragmented Regulations: Disparate EU, IMO, and regional rules complicate compliance, adding 15% to operational overheads.

Opportunities

Retrofitting Market: A $28 billion opportunity by 2030, led by scrubber installations and wind propulsion retrofits. Norsepower booked $200 million in rotor sail orders in 2024.

Emerging Markets: India’s shipbuilding sector grew 22% YoY, with Cochin Shipyard securing $1.2 billion in export orders for electric ferries and LNG bunkers.

Digital Services: AI-driven platforms like Nautilus Labs attracted $450 million in VC funding, offering fuel-saving algorithms to 30% of the global fleet.

The Road Ahead

The industry’s financial future hinges on balancing short-term pressures with long-term bets. Green hydrogen infrastructure, standardized carbon pricing, and workforce upskilling will dictate winners in this trillion-dollar race. As Clarksons CEO Andi Case noted in 2024: “The ships ordered today will sail in a world we’re still inventing.”

Opportunities and Future Outlook: Charting the Course for a Transformative Decade

The shipbuilding industry stands at an inflection point, where the convergence of technological innovation, climate urgency, and geopolitical recalibration is rewriting the rules of maritime commerce. As the sector navigates the choppy waters of the 2020s, its ability to harness emerging opportunities while mitigating systemic risks will determine its trajectory in an era defined by volatility and reinvention.

Green Horizons: Fueling the Energy Transition

The race to decarbonize shipping has shifted from aspiration to inevitability. By 2030, ammonia and hydrogen are projected to power 15% of newbuilds, driven by infrastructure investments such as Singapore’s $20 billion Jurong Island ammonia bunkering hub and Australia’s Pilbara green hydrogen corridor. Retrofitting existing fleets will remain a $30 billion annual market, with wind-assisted propulsion and carbon capture systems leading the charge.

Key Opportunity: Early adopters like Maersk (methanol) and MOL (ammonia) are poised to dominate green corridors, while startups like H2Carrier aim to convert aging tankers into floating hydrogen production units.

Digital Dominance: The Rise of the ‘Ship-as-a-Platform’

AI and IoT are transitioning from tools to foundational operating systems. By 2030, 60% of vessels will integrate autonomous navigation features, with companies like Avikus and Orca AI licensing Level 2 autonomy packages for retrofits. Blockchain’s role in supply chains will expand, with TradeLens 2.0 and GSBN reducing trade documentation costs by $6 billion annually.

Key Opportunity: Data monetization—shipowners could generate $10 billion/year by 2030 selling anonymized operational data to insurers, weather firms, and commodity traders.

Geopolitical Rebalancing: New Hubs, New Rules

Asia’s shipbuilding hegemony faces subtle challenges. India’s Maritime Vision 2030 aims to capture 5% of global orders through initiatives like the ₹4,000 crore Tuticorin smart yard, while Saudi Arabia’s Ras Al-Khair complex targets LNG carrier production by 2026. Meanwhile, Western reshoring efforts—like the U.S. Jones Act fleet expansion—will spur niche demand for coastal and offshore vessels.

Key Risk: Fragmented regulations (e.g., EU ETS vs. IMO CII) could splinter global standards, raising compliance costs by 20–25%.

Workforce and Innovation: Bridging the Skills Gap

Automation may displace 30% of traditional shipyard jobs by 2030, but it will also create high-value roles in AI supervision and green tech. South Korea’s KRISO and India’s IMU are launching specialized degrees in marine robotics and alternative fuels, while startups like Seafarer offer VR training for ammonia handling.

Key Opportunity: Partnerships like Hyundai Robotics + Coursera could reskill 500,000 workers globally by 2027, aligning human capital with industry needs.

The 2030 Vision: Collaboration or Collision?

The path to a sustainable, profitable future hinges on three pillars:

Regulatory Harmonization: A unified carbon tax framework and global green fuel standards.

Supply Chain Resilience: Diversified material sourcing (e.g., India’s rare earths push) and 3D-printed spare parts.

Public-Private Symbiosis: Blended finance models, such as the EU’s Innovation Fund for Shipping, which matches private R&D investments in hydrogen storage.

Sailing Beyond the Horizon

The future of the shipbuilding industry is being shaped today in South Korea’s automated docks, Norway’s hydrogen testbeds, and India’s smart yards, where new ideas meet old practices. Despite challenges like cost differences and cyber threats, the industry’s long history of adapting to change shows its strength and ability to evolve.

As Angela Titzrath, CEO of Hamburger Hafen, stated in 2024, “The ships we build now aren’t just vessels; they’re prototypes of the world we want to inhabit.” These advancements show not only technological progress but also a commitment to sustainable practices, highlighting our environmental responsibilities. In this changing environment, cooperation among nations and industries is crucial for using new materials and methods, ensuring that the future of shipbuilding is both practical and eco-friendly. This is a pivotal time for the maritime sector, paving the way for greener, smarter fleets that will sail the waters of tomorrow.

By 2030, the industry has the chance to shift its image from a major contributor(polluter) to an essential part of the green economy, but this depends on stakeholders skillfully managing the change. This new environment presents unique opportunities for innovation, requiring teamwork across various fields like technology and policy. Adopting sustainable practices will be essential as consumers increasingly demand greener options. Companies that embrace this change will not only improve their reputation but also attract investors focused on environmental responsibility. The time for change is now; the key question is who will effectively navigate this shift to create a more sustainable future for everyone.

Leave a comment