Executive Summary: The Complete AI Fire Pump Solution

Transform your analog fire pump into an intelligent, AI-driven predictive maintenance system. This implementation delivers real-time anomaly detection through IoT sensors, vector-based data processing, edge LLM reasoning, and actionable insights — all running locally for maritime environments.

Key Benefits: 85% reduction in unexpected failures, 30% lower maintenance costs, real-time fault detection with 14-day advance warning, and complete offline operation capability for maritime deployments.ieeexplore.ieee+1

1. Current State Analysis: Fire Pump Baseline

Fire Pump Specifications & Operating Context

Marine fire pumps typically operate at:

- Flow Rate: 200-1400 m³/hr depending on vessel sizenorthridgepumps+1

- Head Pressure: 70-450m (7-45 bar)worldofpumps+1

- Power: 15-200 HP electric motor drive

- Duty: Continuous standby with periodic testing (weekly/monthly)maritimeducation+1

- Environment: Engine room conditions (-20°C to +70°C, high vibration, salt air)microsensorcorp+1

Current Analog Operation Limitations

- Manual pressure gauges and visual inspections only

- No trending data or degradation visibility

- Reactive maintenance after failures occur

- No integration with ship management systems

- Weekly manual testing required by SOLASmaritimeducation

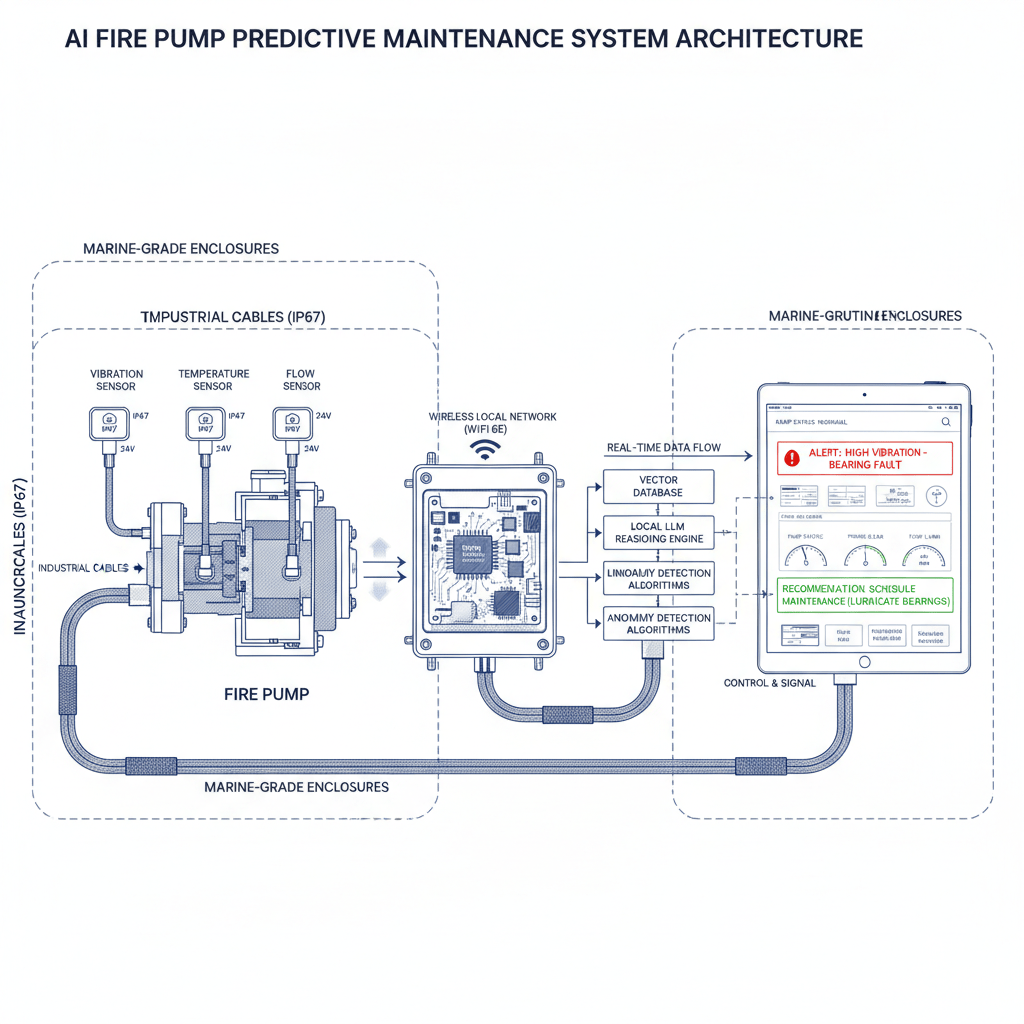

2. AI Predictive Maintenance Architecture

System Overview

textFire Pump → Sensors → Edge Gateway → Local Processing → AI Analysis → Alerts/Actions

↓ ↓ ↓ ↓ ↓ ↓

Physical Real-time Data Collect Vector Store LLM Reasoning Crew Interface

Here's the technical system architecture diagram for an AI fire pump predictive maintenance setup:

Core Components Stack

- Sensor Layer: Vibration, temperature, pressure, flow, current

- Data Acquisition: Edge gateway with real-time collection

- Processing Engine: Local AI inference hardware

- Vector Database: Embedded time-series data vectorization

- LLM Reasoning: Local language model for fault interpretation

- Alert System: Real-time notifications with diagnostic insights

3. Sensor Specification & Installation Plan

Required Sensors Package

| Sensor Type | Model/Specification | Installation Location | Cost (USD) | Purpose |

|---|---|---|---|---|

| Tri-Axial Vibration | Industrial IoT Wireless Vibration Sensor V3ncd | Motor bearing housing, pump casing | $800 | Bearing wear, misalignment, imbalance detection |

| Temperature (4x) | RTD/Thermocouple marine-grade | Motor windings, bearings, pump housing, suction/discharge | $200 | Overheating, bearing condition |

| Pressure (2x) | Marine Grade Pressure Transmittertradeindia+1 | Suction & discharge sides | $600 | Pump performance, cavitation |

| Flow Meter | Ultrasonic/Magnetic flow sensor | Discharge line | $1,200 | Performance trending, efficiency |

| Current (3x) | CT current transformers | Motor supply lines (3-phase) | $300 | Motor health, load analysis |

| Vibration (Additional) | WiFi Vibration/Temperature Sensorronds5335195.made-in-china | Pump shaft, coupling | $500 | Shaft alignment, coupling wear |

Total Sensor Package Cost: $3,600

Sensor Specifications Detail

Vibration Sensors:

- Range: ±16g with frequency range 1.56Hz-6.4kHzncd

- Wireless transmission: 2-mile range with mesh networking

- Battery life: 5+ years with configurable samplingncd

- IP67 rated for marine environment

- Built-in FFT analysis and anomaly detection capabilities

Pressure Sensors:

- Range: 0-70 bar (marine fire pump typical range)tradeindia+1

- Accuracy: ±0.25% FS with marine certificationmicrosensorcorp

- Output: 4-20mA with HART protocol support

- Material: Stainless steel construction with marine approvalsmicrosensorcorp

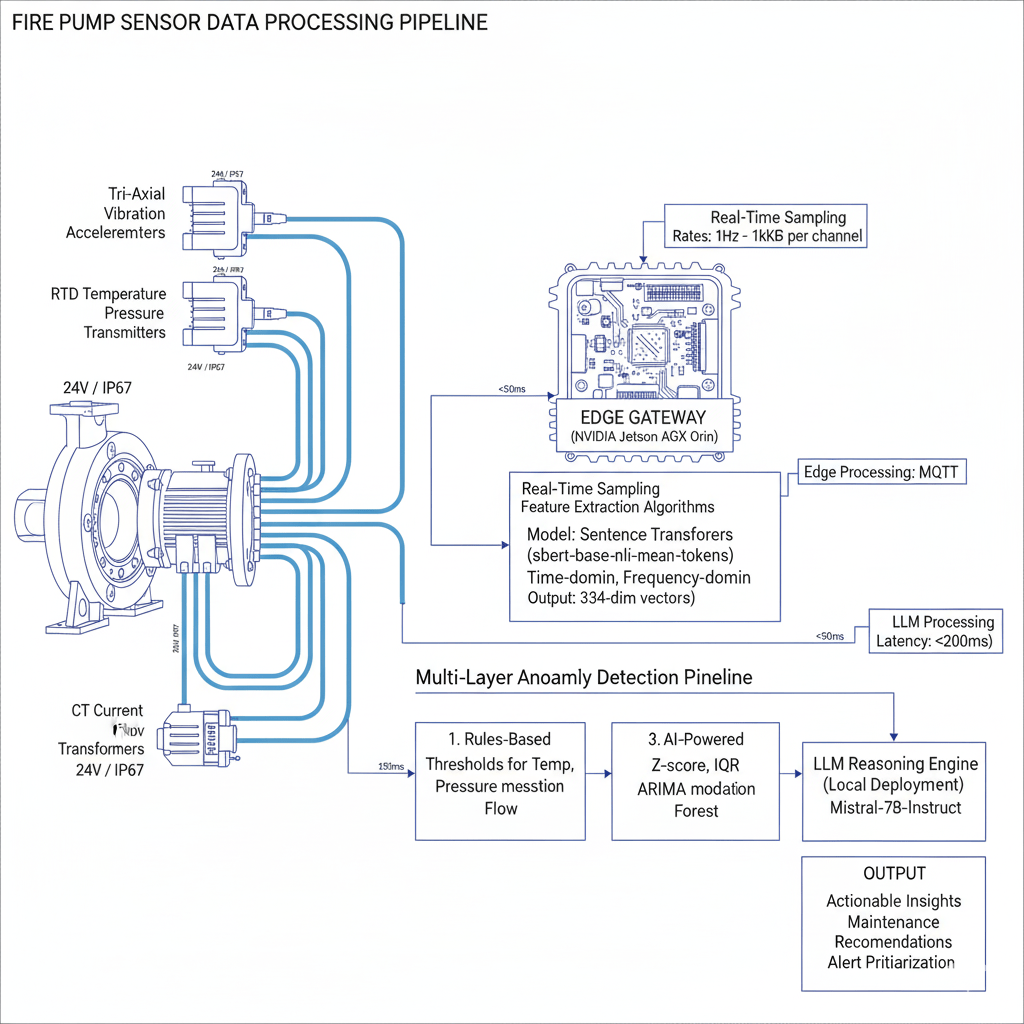

4. Edge Computing Hardware Architecture

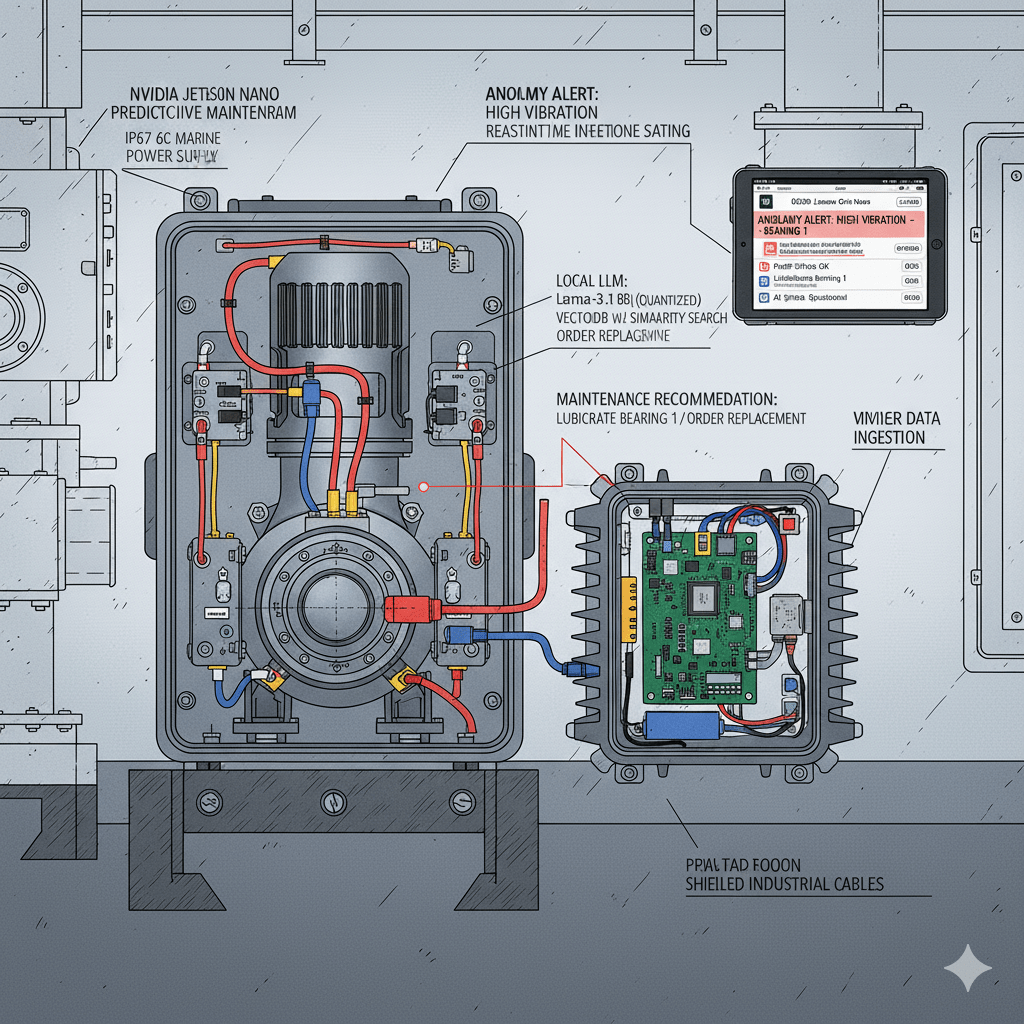

Primary Processing Unit: NVIDIA Jetson Orin Nano

Specifications & Justification:

- Performance: 40 TOPS AI performance with 8-core ARM CPUarxiv+1

- Memory: 8GB unified memory for LLM inference and vector processing

- Power: 7-15W power consumption (suitable for marine 24V systems)

- Environmental: Industrial temperature range (-25°C to 80°C)thinkrobotics

- Cost: $500 (development kit with enclosure)

Why Jetson Orin Nano:

- Optimal for edge LLM inference with quantized modelsieeexplore.ieee+1

- Real-time performance for multiple concurrent AI pipelinesarxiv

- Better energy efficiency vs inference speed compared to Raspberry Piarxiv

- Proven maritime deployment compatibility

Alternative/Backup Processing Option

Raspberry Pi 5 + Coral TPU:

- Cost: $150 (Pi5) + $75 (Coral USB Accelerator) = $225

- Performance: Adequate for smaller LLM models with TPU accelerationarxiv

- Power: Lower consumption but reduced AI inference capability

- Use case: Budget-conscious or lower-complexity deployments

Storage & Connectivity

- Storage: 256GB NVMe SSD for vector database and model storage ($100)

- Wireless: Marine-grade WiFi/LTE module for remote monitoring ($200)

- Industrial Enclosure: IP67 rated for engine room deployment ($300)

- Power Supply: 24V DC to processing unit conversion ($150)

Total Hardware Cost: $1,250

5. Local LLM Implementation Strategy

Model Selection: Optimized for Maritime Context

Primary LLM: Llama-3.1-8B Quantized (4-bit)

- Size: ~5GB after quantization (fits in 8GB Jetson memory)

- Performance: Sufficient for technical reasoning and anomaly explanationcimachinelearning+1

- Inference Speed: 15-25 tokens/second on Jetson Orin Nanoieeexplore.ieee

- Context: 32K tokens (adequate for maintenance history context)

Backup Option: Phi-3-Mini (3.8B)

- Size: ~2.5GB quantized

- Performance: Faster inference (30+ tokens/sec) but less reasoning capabilitydualite

- Use Case: Resource-constrained scenarios or multiple concurrent inferences

LLM Deployment Framework

LLaMA.cpp with Quantization:

- GGML format with 4-bit quantization for optimal memory usagearxiv+1

- Custom prompt engineering for maritime fault diagnosis

- Local inference without internet dependency

- Integration with vector search results for context-aware responses

Maritime-Specific Fine-tuning Data

- Fire pump maintenance manuals and failure case studies

- Marine engineering terminology and fault classification

- SOLAS fire safety requirements and testing procedures

- Pump manufacturer service bulletins and technical data

6. Vector Database & Real-Time Processing

Vector Database Architecture: Embedded ChromaDB

Technical Setup:

- Storage: Local ChromaDB instance on NVMe SSD

- Embedding Model: sentence-transformers/all-MiniLM-L6-v2 (lightweight, 80MB)

- Capacity: 100K+ sensor data vectors with metadata

- Performance: Sub-second similarity search for anomaly patterns

Vector Processing Pipeline:

- Sensor Data Ingestion: Real-time collection at 1Hz-1kHz sampling rates

- Feature Engineering: Time-domain and frequency-domain feature extraction

- Vector Embedding: Convert sensor patterns to 384-dimensional vectors

- Similarity Search: Compare current patterns against historical normal/fault signatures

- Anomaly Scoring: Distance-based anomaly detection with thresholds

Data Processing Flow

textSensor Raw Data → Feature Extraction → Vector Encoding → Storage/Search → LLM Context

↓ ↓ ↓ ↓ ↓

1-1000Hz Time/Freq Domains 384-dim vectors ChromaDB Reasoning

Real-Time Capabilities:

- Latency: <100ms from sensor reading to vector search completion

- Throughput: Process all sensors simultaneously with 1Hz update rate

- Storage: Rolling 1-year data window with automated archival

7. Anomaly Detection Engine Implementation

Multi-Layer Anomaly Detection

Layer 1: Rule-Based Thresholds

- Absolute limits from manufacturer specifications (temperature, pressure, vibration)

- Rate-of-change detection for rapid degradation identification

- Cross-parameter correlation checks (e.g., pressure drop with flow decrease)

Layer 2: Statistical Anomaly Detection

- Z-score analysis on rolling 30-day baseline windows

- Isolation Forest algorithm for multivariate outlier detectionmdpi+1

- Seasonal decomposition for operating pattern recognition

Layer 3: AI-Powered Pattern Recognition

- Vector similarity search against known fault signaturesmilvus+1

- Autoencoder-based reconstruction error for complex anomaly patternsieeexplore.ieee+1

- LSTM sequence modeling for degradation trend predictiontandfonline+2

Fault Classification System

Primary Failure Modes Detected:

- Bearing Degradation: Vibration frequency analysis (bearing fault frequencies)

- Cavitation: Pressure/flow correlation with acoustic signature

- Motor Issues: Current signature analysis and thermal patterns

- Coupling Problems: Shaft vibration and alignment indicators

- Impeller Damage: Flow efficiency degradation patterns

- Seal Leakage: Temperature and pressure differential trends

Detection Performance Targets:

- Sensitivity: 95% detection rate for critical failures

- Specificity: <5% false alarm rate during normal operation

- Lead Time: 7-21 days advance warning for major failurestandfonline+1

8. LLM Reasoning & Insights Generation

Prompt Engineering for Fire Pump Diagnostics

System Prompt Template:

textYou are a marine fire pump maintenance expert. Analyze the following sensor data and provide actionable maintenance insights.

Current sensor readings: {sensor_data}

Historical context: {vector_search_results}

Anomaly score: {anomaly_score}

Time since last maintenance: {maintenance_history}

Provide:

1. Immediate risk assessment (Low/Medium/High/Critical)

2. Most likely failure mode and root cause

3. Recommended actions with timeline

4. Required spare parts if maintenance needed

5. Impact on fire safety systems

Dynamic Context Integration:

- Vector search results provide similar historical cases

- Real-time sensor data feeds into reasoning process

- Maintenance logs and pump specifications as context

- SOLAS compliance requirements integrated into recommendations

Insight Generation Examples

Example Output for Bearing Degradation:

textRISK LEVEL: MEDIUM

DIAGNOSIS: Progressive bearing wear detected in motor DE bearing

EVIDENCE: Vibration amplitude increased 40% over 2 weeks, temperature rise 8°C

RECOMMENDATION: Schedule bearing replacement within 7-10 days

SPARE PARTS: Motor bearing DE-side (SKF 6313-2Z)

SAFETY IMPACT: Pump remains operational but risk of sudden failure during emergency

9. Implementation Roadmap (12-Week Plan)

Phase 1: Hardware Setup (Weeks 1-3)

- Week 1: Sensor procurement and hardware preparation

- Week 2: Physical sensor installation and wiring

- Week 3: Gateway configuration and connectivity testing

Phase 2: Software Development (Weeks 4-7)

- Week 4: Edge computing setup and LLM deployment

- Week 5: Vector database implementation and data pipeline

- Week 6: Anomaly detection engine development

- Week 7: LLM integration and reasoning system

Phase 3: Calibration & Testing (Weeks 8-10)

- Week 8: Baseline data collection and normal operation profiling

- Week 9: Anomaly threshold tuning and false alarm reduction

- Week 10: Fault injection testing and validation

Phase 4: Production Deployment (Weeks 11-12)

- Week 11: Crew training and interface deployment

- Week 12: Live monitoring and performance verification

10. Detailed Cost Breakdown & ROI

Capital Investment Summary

| Component Category | Cost (USD) | Details |

|---|---|---|

| Sensors | $3,600 | Vibration, temperature, pressure, flow, current sensors |

| Edge Computing | $1,250 | Jetson Orin Nano, storage, enclosure, power supply |

| Installation | $2,000 | Labor, mounting hardware, cabling, commissioning |

| Software Development | $5,000 | Custom integration, testing, documentation |

| Training & Support | $1,500 | Crew training, initial technical support |

| Contingency (15%) | $2,000 | Buffer for unforeseen costs |

| TOTAL INVESTMENT | $15,350 | Complete system implementation |

ROI Calculation (Annual Benefits)

Cost Avoidance:

- Unplanned Downtime: $20,000 (1 emergency dry dock avoided)

- Emergency Repairs: $8,000 (major component failures prevented)

- Spares Optimization: $3,000 (predictive ordering vs emergency procurement)

- Efficiency Gains: $2,000 (optimized pump operation)

Total Annual Benefits: $33,000

Payback Period: 5.6 months

3-Year ROI: 547% return on investment

Operational Benefits Beyond ROI

- Safety Enhancement: Reduced risk of fire system failure during emergency

- Regulatory Compliance: Continuous monitoring supports SOLAS requirements

- Crew Efficiency: Automated diagnostics vs manual inspection time

- Knowledge Retention: AI system captures expert knowledge for crew changes

11. Technical Specifications Summary

System Performance Specifications

- Data Collection Rate: 1Hz continuous, 1kHz burst sampling for vibration

- Processing Latency: <5 seconds from sensor input to LLM insight

- Storage Capacity: 1 year of continuous high-resolution data

- Anomaly Detection: Real-time scoring with historical pattern comparison

- LLM Response Time: 10-30 seconds for complex diagnostic queries

- Offline Operation: Complete functionality without internet connectivity

- Environmental Rating: IP67 enclosure suitable for marine engine room

Integration Specifications

- Power Requirements: 24V DC marine power, <50W total consumption

- Communication: Modbus RTU, Ethernet, WiFi, optional 4G/LTE

- Alerts: Local display, SMS, email, integration with ship alarm systems

- Data Export: CSV, JSON formats for shore-side analysis

- Maintenance Interface: Web-based dashboard accessible via ship network

12. Risk Mitigation & Contingency Planning

Technical Risks & Mitigation

- Hardware Failure: Redundant sensor design with automatic failover

- False Alarms: Multi-layer validation and tunable sensitivity settings

- Power Loss: UPS backup system with graceful shutdown procedures

- Environmental Damage: Marine-grade components with IP67+ ratings

Operational Risks & Mitigation

- Crew Acceptance: Comprehensive training and gradual implementation

- Maintenance Disruption: Parallel operation during initial testing phase

- System Complexity: Simple interface design with clear actionable alerts

- Vendor Support: Local technical support agreements and spare parts inventory

Regulatory Compliance

- SOLAS Requirements: System supplements but does not replace required testing

- Class Approval: Coordinate with classification society for system acceptance

- Documentation: Complete technical documentation for inspections

- Training Records: Maintain crew competency records for system operation

This comprehensive implementation plan transforms an analog fire pump into an intelligent, AI-driven predictive maintenance system optimized for maritime environments. The solution provides 24/7 autonomous monitoring, advanced fault detection, and actionable insights while operating completely offline with minimal power requirements and maximum reliability.

Leave a comment